Accurate drywall estimating is one of the most important skills a contractor can develop. Whether you’re bidding on residential renovations, commercial build-outs, or large-scale developments, your profitability depends on precise quantity takeoffs and labor projections. Even small calculation errors can lead to material shortages, cost overruns, or lost bids.In this guide, we’ll break down the essential drywall estimating formulas every contractor should know, along with practical examples you can apply immediately to your projects.

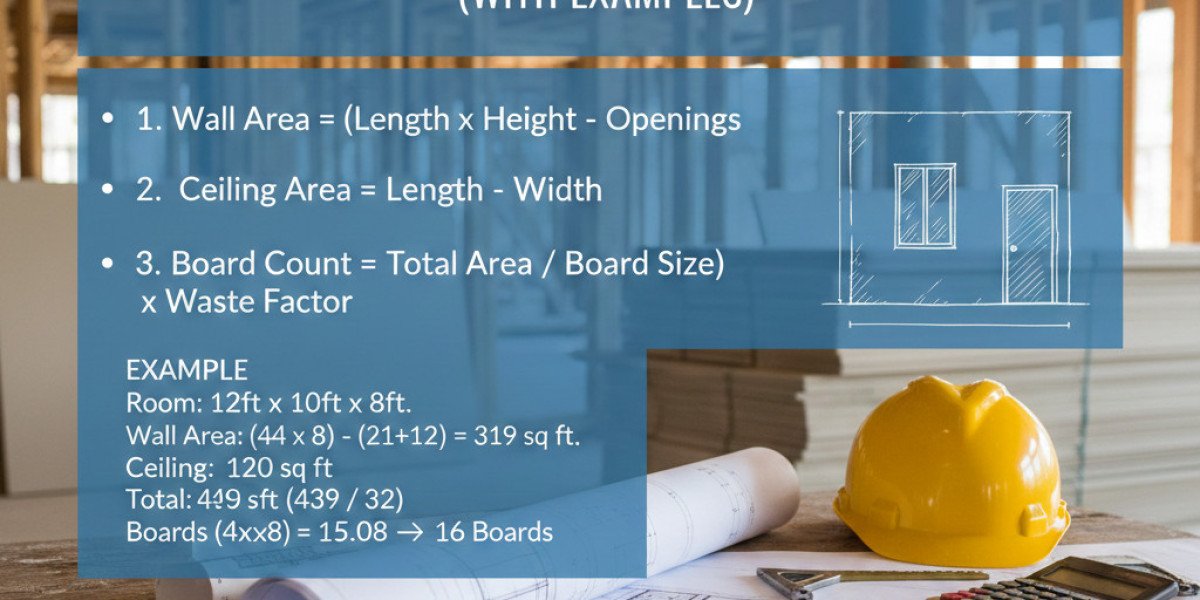

Drywall Sheet Calculation Formula

The foundation of any drywall estimate begins with calculating the number of sheets required.

Formula.

Total Wall Area ÷ Area of One Drywall Sheet = Number of Sheets Required

Step 1: Calculate Wall Area

Wall Area = Length × Height

If you’re working with multiple walls, calculate each separately and add them together.

Example:

Room dimensions: 12 ft × 10 ft

Wall height: 8 ft

Perimeter = (12 + 10 + 12 + 10) = 44 ft

Wall Area = 44 × 8 = 352 sq ft

If using standard 4 ft × 8 ft drywall sheets:

Sheet Area = 4 × 8 = 32 sq ft

Sheets Needed = 352 ÷ 32 = 11 sheets

Always round up to account for cuts and waste.

Ceiling Drywall Calculation

Ceilings require a separate area calculation.

Formula:

Ceiling Area = Length × Width

Example:

For a 12 ft × 10 ft room:

Ceiling Area = 12 × 10 = 120 sq ft

Sheets Needed = 120 ÷ 32 = 3.75

Round up to 4 sheets.

Waste Factor Formula

No drywall job is completed without material waste due to offcuts, mistakes, or irregular layouts.

Standard Waste Percentage

Residential projects: 5%–10%

Commercial projects: 10%–15%

Formula

Total Sheets × Waste Percentage = Additional Sheets Required

Example

If your project requires 15 sheets:

Waste (10%) = 15 × 0.10 = 1.5 sheets

Round up to 2 additional sheets.

Total order: 17 sheets.

Labor Cost Estimation Formula

Labor often represents a large portion of drywall project costs.

Basic Formula

Total Square Footage ÷ Production Rate = Labor Hours

Average Production Rates

Hanging drywall: 40–60 sheets per day (crew dependent)

Finishing drywall: 800–1,000 sq ft per day

Example:

Total Area = 1,200 sq ft

Production Rate = 900 sq ft per day

Days Required = 1,200 ÷ 900 = 1.33 days

Multiply by crew size and hourly rate for total labor cost.

Drywall Screws Estimation Formula

Underestimating fasteners can delay a job.

Industry Rule of Thumb

1 pound of screws per 100 sq ft

Approximately 30–40 screws per 4×8 sheet

Formula:

Total Sheets × Screws Per Sheet

Example:

20 sheets × 35 screws = 700 screws

Add 5–10% buffer for safety.

Joint Compound (Mud) Estimation Formula

Joint compound usage depends on finish level.

Average Coverage:

1 gallon per 100–150 sq ft (Level 4 finish)

Formula:

Total Square Footage ÷ Coverage Rate

Example:

1,000 sq ft project

Coverage Rate: 125 sq ft per gallon

1,000 ÷ 125 = 8 gallons

Adjust upward for higher finish levels.

Drywall Tape Calculation

Tape is typically estimated based on linear feet of joints.

Basic Estimation:

One 4×8 sheet requires about 20–25 linear feet of tape

Formula:

Number of Sheets × Average Tape Length

Example:

15 sheets × 22 ft = 330 linear feet

Purchase rolls accordingly.

Corner Bead Estimation Formula

Corner beads are required for exposed outside corners.

Formula:

Number of Outside Corners × Wall Height

Example:

If you have 6 outside corners in an 8 ft high room:

6 × 8 = 48 linear feet

Always add 5% extra for cutting waste.

Cost Per Square Foot Formula

Many contractors price drywall jobs by square footage.

Formula:

Total Project Cost ÷ Total Square Footage

Example:

Total cost: $3,600

Total area: 1,200 sq ft

Cost per sq ft = $3.00

This metric helps compare project profitability and improve bidding accuracy.

1Markup Formula for Profit

Estimating isn’t just about costs, it's about profit.

Formula:

Total Cost × Markup Percentage = Selling Price

Example:

Project cost = $5,000

Markup = 20%

Selling Price = 5,000 × 1.20 = $6,000

Never confuse markup with margin; this is a common mistake among contractors.

Productivity Adjustment Formula

Different project conditions affect production:

High ceilings

Tight spaces

Complex layouts

Multi-story buildings

Formula:

Base Labor Hours × Difficulty Factor

If a job is 20% more complex:

Labor Hours × 1.20

Example:

Base labor = 40 hours

Adjusted = 40 × 1.20 = 48 hours

This prevents underbidding complex jobs.

Comprehensive Example: Full Room Estimate

Let’s combine everything.

Room: 15 ft × 12 ft × 9 ft height

Step 1: Wall Area

Perimeter = (15 + 12 + 15 + 12) = 54 ft

Wall Area = 54 × 9 = 486 sq ft

Step 2: Ceiling Area

15 × 12 = 180 sq ft

Step 3: Total Area

486 + 180 = 666 sq ft

Step 4: Sheets Required

666 ÷ 32 = 20.8 sheets

Round up = 21 sheets

Add 10% waste:

21 × 0.10 = 2.1 → 3 sheets

Total = 24 sheets

Step 5: Screws

24 × 35 = 840 screws

Step 6: Joint Compound

666 ÷ 125 = 5.3 gallons

Round up = 6 gallons

This systematic approach ensures accuracy and confidence when submitting bids.

Why Mastering Drywall Estimating Formulas Matters

Contractors who rely on guesswork often face.

Budget overruns

Material shortages

Reduced profit margins

Lost competitive bids

Accurate drywall estimating allows you to.

Improve bid confidence

Reduce waste

Increase profitability

Streamline project management

Professional takeoff services like Universe Estimating help contractors scale operations by providing detailed quantity takeoffs and cost analysis, ensuring every formula is applied correctly.

Pro Tips for Better Drywall Estimates

Always verify field measurements twice.

Separate walls and ceilings in calculations.

Include doors and window deductions only if significant.

Factor in ceiling height changes.

Track historical job data for improved accuracy.

Adjust production rates based on crew experience.

Include delivery and equipment costs.

The more data you collect from completed projects, the more precise your future estimates will become.

Final Thoughts

Drywall estimating is both a science and an art. The science lies in understanding and applying the right formulas from sheet count calculations to labor productivity adjustments. The art comes from experience, job condition awareness, and market knowledge.By mastering these essential drywall estimating formulas, contractors can submit competitive bids while protecting profit margins. Whether you’re handling small residential jobs or large commercial builds, accurate calculations will always be your strongest competitive advantage.Use these formulas consistently, refine them with real project data, and you’ll build a reputation for precision and reliability in every bid you submit.