Labeling rolls serve as an integral component in various industries, enabling precise and efficient product identification. Their importance lies in their ability to streamline processes such as inventory management, regulatory compliance, and branding efforts. With a wide range of applications, they support industries including food and beverage, healthcare, and retail by ensuring vital information is clearly conveyed. Labeling rolls contribute to operational efficiency by aiding in the organization and categorization of products, facilitating smooth workflows. Their adaptability, stemming from diverse materials and formats, ensures they meet the specific requirements of different sectors. Additionally, label rolls play a significant role in maintaining product presentation and conveying essential data, such as instructions and safety information, to end-users. This versatility highlights their important function in supporting businesses across various operational and marketing endeavors.

Types of Materials Used in Labeling Rolls

Labelling rolls are manufactured using various materials to address diverse industrial needs. Paper-based labels are a commonly used option, valued for their affordability and suitability in applications where durability is secondary. Plastic materials, including polypropylene and polyester, offer increased resilience, making them ideal for exposure to moisture, chemicals, or physical wear. For industries focusing on environmental responsibility, biodegradable and recycled materials are available, promoting sustainable practices without compromising quality.

Specialised materials, such as heat-resistant or tamper-evident options, cater to niche requirements, ensuring compatibility with specific operational conditions. Each material offers unique properties, allowing labelling rolls to perform effectively across different sectors. Careful selection of material ensures alignment with product-specific demands and environmental considerations, enhancing functionality and meeting regulatory standards.

Common Applications of Labelling Rolls

Labelling rolls are utilised extensively across multiple industries to meet various functional and regulatory requirements. In the retail sector, they are essential for facilitating product identification, price labelling, and inventory organisation, ensuring seamless operations. The food and beverage industry relies on these rolls to display critical details such as nutritional content, storage guidelines, and batch information, which are vital for consumer trust and safety.

Healthcare applications include labelling pharmaceutical products and medical devices with important details such as dosage instructions, lot numbers, and expiration dates to maintain compliance and patient safety. In logistics and warehousing, labelling rolls play a key role in tracking shipments, organising inventory, and improving supply chain management. These diverse applications underline the significance of labelling rolls in maintaining efficient processes while ensuring that essential information is clearly and reliably communicated.

Design Considerations for Effective Labelling

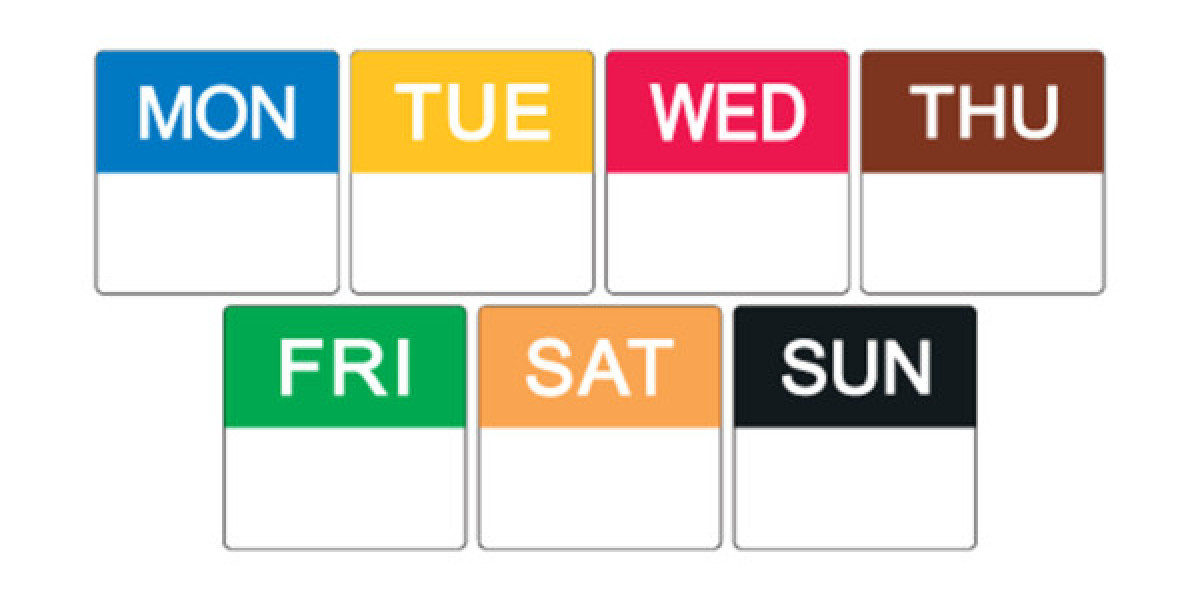

A well-crafted label design enhances both functionality and visual appeal. The choice of colours plays a crucial role, helping to attract attention and reinforce brand identity when used effectively. Typography selection is equally important, as legibility ensures that essential information is conveyed at a glance. Incorporating appropriate imagery or symbols can add clarity or visual interest, making the label more impactful. The placement of design elements should create a balanced layout, avoiding overcrowding while maintaining a clear hierarchy of information.

Material selection also influences the overall appearance and durability, ensuring the label aligns with the intended use. Additionally, finishes such as matte, gloss, or textured coatings can enhance the tactile and aesthetic qualities of the label. Attention to these design details ensures that labelling achieves its practical purposes while complementing the product’s presentation.

Labelling Roll Sizes and Formats

Labelling rolls are designed in a variety of sizes and formats to suit distinct operational needs. Customised dimensions cater to specialised applications, such as labelling uniquely shaped products or ensuring compatibility with specific labelling machinery. Standardised sizes, on the other hand, provide a practical solution for general labelling tasks, ensuring versatility across various sectors.

Formats can include options tailored for automated systems, allowing seamless integration into production lines, or manual processes, which require ease of handling and application. The choice of size and format directly impacts the efficiency of labelling processes, as well as the overall appearance of the final product. Considering factors such as machine compatibility, application method, and end-use ensures that labelling rolls are not only functional but also contribute effectively to streamlined workflows.

Printing Techniques for Label Rolls

Different printing techniques are utilised to ensure Label Rolls meet varying industry requirements. Digital printing stands out for its ability to handle complex designs and variable data with high precision, making it suitable for small to medium-scale projects. Flexographic printing, recognised for its speed and efficiency, is favoured for high-volume production while maintaining consistent quality.

Offset printing excels in delivering sharp details and vibrant colours, often chosen for intricate or high-resolution designs. Thermal printing is widely used for barcode and shipping labels, offering reliability for on-demand applications. Each method has unique advantages, tailored to specific labelling needs, including cost considerations, production scale, and design complexity. Selecting the appropriate technique depends on the intended use, ensuring the labels meet both functional and aesthetic standards while aligning with operational demands.

Adhesive Types in Labelling Rolls

Adhesives play a vital role in ensuring the effectiveness of labelling rolls, with different types designed to meet specific application requirements. Pressure-sensitive adhesives are widely used due to their versatility, offering reliable bonding on a variety of surfaces with minimal application effort. For situations requiring removability, low-tack adhesives allow labels to be removed cleanly without leaving residue, making them ideal for temporary use.

High-tack adhesives provide a strong bond for challenging conditions, such as exposure to moisture or rough surfaces. Heat-activated adhesives, on the other hand, require heat to form a bond, making them suitable for specialised applications. Other options include repositionable adhesives, which allow adjustments during application without compromising adhesion. The careful selection of adhesive type ensures optimal performance, meeting both functional and environmental demands while addressing diverse industry-specific requirements.

Regulations and Compliance in Labelling

Regulations in labelling are established to ensure transparency, safety, and standardisation across industries. Specific sectors, such as food, healthcare, and chemicals, mandate the inclusion of precise details like ingredients, warnings, or hazardous material symbols to safeguard public health and promote informed decisions.

Labelling rolls must also adhere to environmental directives, which may involve using recyclable materials or reducing waste. Meeting international standards, such as those set by ISO, guarantees that labels comply with global trade requirements.

Maintaining alignment with these regulations necessitates ongoing updates to labelling practices as standards evolve. Compliance with such rules ensures labelling accuracy, minimises legal risks, and upholds consumer trust while contributing to a well-regulated and responsible industry landscape.

Storage and Handling of Labelling Rolls

Labelling rolls require careful management to preserve their quality and usability. Proper storage involves keeping them in a dry and stable environment, away from direct sunlight and extreme temperatures, to prevent adhesive deterioration or material warping. Handling practices should prioritise avoiding unnecessary exposure to dust, dirt, or physical pressure, which could compromise the label’s surface or adhesive properties.

Rolls should be stored in their original packaging or protective coverings to minimise the risk of contamination or damage during transportation or storage. When stacking rolls, attention should be given to ensuring they are not subjected to excessive weight or pressure, which could lead to deformation. Adopting such measures ensures consistent performance during application and production processes.

Technology Advancements in Labelling

Innovations in labelling technology continue to transform the way information is communicated and managed across industries. The incorporation of smart labels featuring sensors enhances functionality by providing real-time data, such as temperature or humidity levels, ensuring better product monitoring. RFID-enabled labels improve operational efficiency by simplifying inventory tracking and enhancing supply chain visibility.

Developments in digital integration are enabling the use of QR codes and interactive labels, offering access to detailed product information and improving consumer engagement. Automation advancements in labelling systems further enhance precision and reduce labour-intensive tasks, particularly in high-volume production environments. These technological progressions reflect the evolving demands of industries, supporting greater accuracy, traceability, and connectivity within labelling processes.

Cost Considerations for Labelling Rolls

The cost of labelling rolls is influenced by various factors, including the choice of materials, printing methods, and the level of customisation required. High-quality materials, such as durable plastics or specialised finishes, may incur higher costs but provide greater longevity and functionality. Advanced printing techniques, while offering intricate designs or variable data capabilities, can also impact overall expenses.

Additionally, tailored specifications, such as unique dimensions or adhesive types, contribute to the pricing structure. Bulk ordering is an effective way to manage costs for large-scale requirements, as it reduces the per-unit expense. Understanding the specific demands of the application ensures that resources are utilised efficiently, allowing industries to achieve optimal outcomes within their allocated budgets.

Choosing the Right Labelling Rolls for Your Needs

Selecting suitable labelling rolls involves evaluating factors such as environmental conditions, surface compatibility, and required durability. Consideration should be given to the specific operational demands, such as exposure to moisture, temperature fluctuations, or chemicals. The choice of adhesive and material must align with these conditions to ensure consistent performance.

Assessing application methods, whether manual or automated, is equally crucial to guarantee seamless integration into existing workflows. Reviewing technical specifications and consulting industry guidelines helps in identifying options that balance functionality, cost-effectiveness, and regulatory compliance. Such an approach ensures labelling rolls effectively fulfil their intended purpose across diverse applications.

Conclusion

Label Rolls are a cornerstone of operational efficiency across all Australian industries, from food manufacturing to logistics and healthcare. They are vital for enabling high-speed automated processes, which significantly cut down on production time and reduce manual errors associated with product identification and compliance documentation. Their versatility allows for the use of specialised materials and adhesives to suit any environment, ensuring that critical data, from batch traceability to mandatory regulatory information, is applied precisely, consistently, and durablely, thereby upholding safety standards and strengthening supply chain integrity.

Frequently Asked Questions

How do labels on a roll help in managing complex logistics operations?

Labels on a roll are the backbone of logistics by supporting high-speed, automated tracking. They carry crucial barcodes, QR codes, and addresses that are machine-readable. Since they are fed continuously through thermal printers, logistics centres can generate and apply thousands of unique shipping labels quickly, enabling real-time scanning and tracing throughout the entire supply chain, which ensures rapid, accurate sorting and timely delivery.

What are the main differences between flexographic and digital printing for Label Rolls?

Flexographic printing of Label Rolls uses flexible relief plates and is ideal for large-volume, high-speed production with a focus on cost-efficiency and consistent colour matching, though setup costs are higher. Digital printing involves no plates, making it perfect for short runs, variable data printing (like sequential serial numbers or individual names), and intricate, full-colour designs with lower initial setup costs but potentially higher per-unit costs at extremely high volumes.

Why is the choice of adhesive on a label roll as important as the material?

The adhesive is critical because it dictates how and where the label can be applied and for how long it will perform. A label meant for frozen food requires a freezer-grade adhesive that won't fail in cold temperatures, while a temporary price tag needs a low-tack removable adhesive to prevent residue. Choosing the wrong adhesive can cause the label to fall off, curl, or damage the product surface, jeopardising both safety and branding.

How do smart labels improve efficiency over traditional barcode labels?

Smart labels, often containing RFID (Radio Frequency Identification) technology , improve efficiency by allowing contactless, bulk scanning . Unlike traditional barcodes, which require a direct line of sight scan of one item at a time, RFID labels can be read simultaneously from a distance, significantly rapidly inventory counts, checking shipments, and asset tracking in large, high-density environments like warehouses.

What regulatory information must be included on a food industry label roll?

Food industry labels must mandatorily include nutritional information (eg, macro-nutrients, energy), a complete and accurate ingredient list , clear declaration of all allergens (often in bold type), the net weight or volume , and a use-by or best-before date . These details are essential for consumer safety and legal compliance, ensuring accurate information is conveyed before purchase and consumption.

Related Business Listings |