In the jewellery industry, even the smallest imperfection can impact the beauty and value of a piece. Traditional welding often risks damaging gemstones or altering metal properties due to excessive heat. The jewellery laser welding machine eliminates these risks by providing a highly focused beam that melts metals precisely where needed without affecting surrounding areas. This controlled process preserves the aesthetics and integrity of delicate jewellery components, allowing artisans to deliver flawless outcomes every time.

The Core Principle of Laser Welding in Jewellery

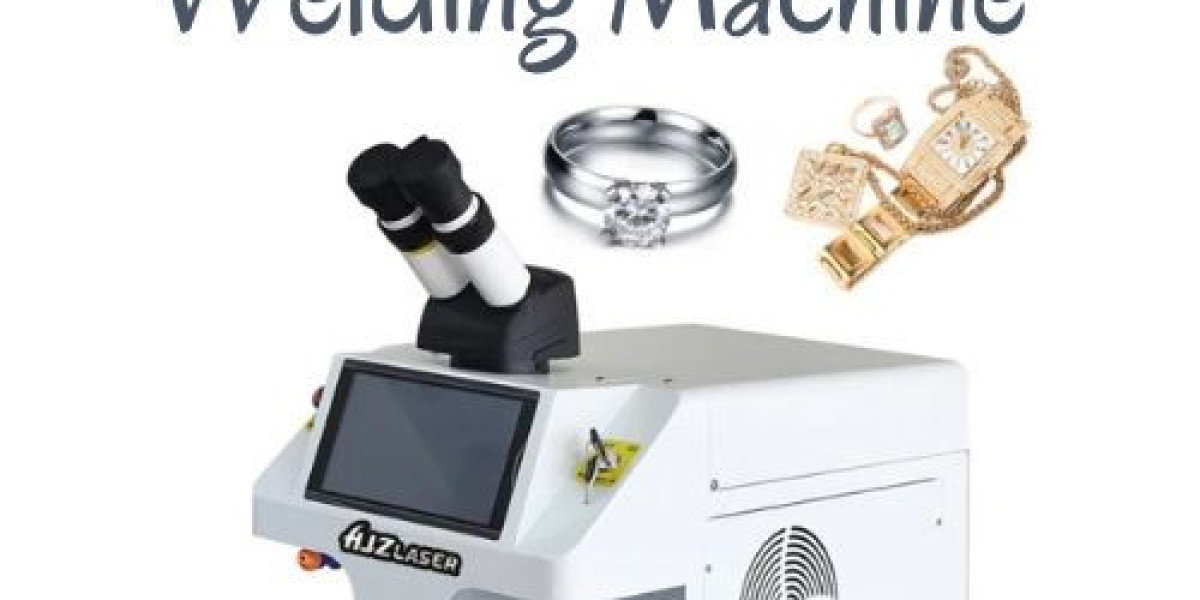

The jewellery laser welding machine works on the principle of concentrated laser energy that joins metal surfaces by melting them together at a microscopic level. Instead of using filler materials or high temperatures, it relies on controlled laser pulses to fuse metals seamlessly. The precision of this method ensures that the joints are strong, clean, and nearly invisible.

Jewelers often deal with complex materials such as gold, silver, platinum, and titanium. Each of these metals has distinct melting points and behaviors under heat. The laser welding machine allows jewelers to adjust the laser’s intensity, frequency, and duration based on the metal type, ensuring the right level of energy is delivered every time. This adaptability makes it a universal solution across multiple jewellery applications.

Applications of Jewellery Laser Welding Machine

The jewellery laser welding machine finds its place across every corner of the jewellery workshop. From crafting new designs to restoring old pieces, it serves a broad range of purposes:

Repairing Broken Chains and Clasps – The machine can reconnect fine chain links without altering the appearance or causing discoloration.

Ring Resizing and Setting Adjustments – Jewelers use it to resize rings or secure loose gemstone settings with extreme accuracy.

Engraving and Personalization – Beyond welding, certain laser systems can also engrave intricate patterns or initials on jewellery surfaces.

Restoration of Antique Jewellery – It helps revive delicate vintage pieces by repairing micro fractures or broken joints without further stress on the metal.

Manufacturing New Jewellery Designs – Designers use laser welding to assemble complex multi-metal combinations with smooth transitions and perfect symmetry.

Each of these applications demonstrates how indispensable the jewellery laser welding machine has become in both small-scale studios and large jewellery production houses.

Precision Without Heat Damage

One of the main reasons for the growing popularity of the jewellery laser welding machine is its ability to perform without excessive heat spread. Traditional flame or torch welding can easily harm heat-sensitive materials like gemstones, enamel, or filigree decorations. However, laser welding focuses on a microscopic area, keeping the surrounding region cool. This means even precious stones such as emeralds, sapphires, or pearls can stay in place during welding operations.

This precision also helps reduce post-processing work. Jewelers spend less time polishing or cleaning joints, which increases overall productivity while maintaining the handmade touch that defines authentic jewellery artistry.

Efficiency and Accuracy in Daily Operations

In a modern jewellery workshop, time efficiency is vital. The jewellery laser welding machine allows artisans to perform multiple operations in minutes that would traditionally take hours. Its digital control interface ensures repeatable results, making it easier to maintain consistent quality in production batches.

The ability to work under a microscope gives the operator a detailed view of the welding zone. Even at high magnifications, the laser remains steady and accurate. This level of precision opens creative possibilities for micro-welding tasks where manual techniques simply fall short.

The Role of Technology in Jewellery Innovation

The introduction of jewellery laser welding machines has elevated the craftsmanship standard in the jewellery market. They have empowered both new and experienced artisans to explore innovative designs that were once considered too complex or risky to manufacture.

For example, combining different metals such as gold and platinum or incorporating ultra-thin components is now achievable. The laser’s pinpoint control allows for joining these materials without compromising durability. Designers can experiment freely while maintaining the structural integrity of their creations.

Supporting Sustainable Jewellery Practices

Sustainability is increasingly becoming a focal point in the jewellery industry. The jewellery laser welding machine contributes to eco-friendly manufacturing by reducing material waste. Since it works with extreme accuracy, only the necessary amount of metal is melted, leaving minimal residue.

Additionally, this method reduces the need for chemical fluxes and soldering materials often used in traditional welding. This not only minimizes environmental impact but also improves workplace safety by avoiding harmful fumes or residues.

Recycling old or damaged jewellery is another area where the machine plays a key role. Jewelers can efficiently rework old pieces into new designs by welding without weakening the metal, supporting a circular and responsible approach to jewellery making.

Training and Skill Development

Operating a jewellery laser welding machine requires precision and understanding, but with the right training, even small workshops can integrate this technology effectively. Many modern models are user-friendly, with touch-screen interfaces, adjustable parameters, and built-in microscopes for detailed work.

Workshops and training programs now include laser welding as part of their professional development for jewelers. This ensures that the new generation of craftsmen can handle both traditional artistry and modern laser-based techniques with confidence.

Industrial Adaptability and Customization

Every jewellery business has unique requirements, from small boutiques to large-scale manufacturers. The jewellery laser welding machine is available in various power capacities and configurations, ensuring that each workshop finds the perfect match for its workload.

Portable models are ideal for small repair studios or mobile services, while high-power industrial units support continuous production lines. Customization options such as foot pedal control, pulse shaping, and advanced cooling systems enhance usability and efficiency for diverse working environments.

Maintenance and Longevity

Proper maintenance ensures long-term reliability of the jewellery laser welding machine. Regular cleaning of the optical path, calibration of laser parameters, and cooling system checks are essential. Most modern machines feature self-diagnostic systems that alert users of any performance inconsistencies, allowing preventive action before major repairs are needed.

A well-maintained machine can serve effectively for many years, delivering consistent quality and reducing operational costs. This long lifespan contributes to the overall cost-efficiency and sustainability of the workshop.

Final Thoughts

The jewellery laser welding machine has revolutionized the jewellery industry by merging precision technology with the delicate art of craftsmanship. It allows jewelers to perform intricate welding tasks without compromising design, safety, or efficiency. From high-end luxury brands to small custom workshops, this machine has become a vital tool for anyone seeking superior quality and accuracy in jewellery making.

As the demand for refined and sustainable jewellery continues to rise, adopting the jewellery laser welding machine is no longer a luxury—it’s an essential step toward achieving perfection in modern jewellery design and repair.