In industries where Disposable Gloves Supplier are essential, selecting the right supplier significantly impacts operational efficiency and safety compliance. A dependable supplier ensures not only a steady supply but also that the gloves meet required hygiene and quality standards. Evaluate suppliers who provide diverse glove options tailored to specific industry needs, such as nitrile for chemical resistance or vinyl for affordability in high-turnover environments.

H3 Verify Supplier Certifications and Compliance

Always confirm that the supplier holds certifications aligning with industry and regulatory requirements, such as EN standards. This guarantees that their products have undergone rigorous testing for safety and performance.

Additionally, consider the supplier's ability to accommodate sudden demand surges, which is particularly critical in healthcare or food services. Collaborating with a supplier who demonstrates flexibility, reliability, and an understanding of your sector’s requirements minimises risks and supports uninterrupted operations.

Key Factors in Choosing a Gloves Supplier Australia

When selecting a Gloves Supplier Australia, prioritise suppliers offering products that meet stringent Australian safety and quality standards. Research their product range to ensure they provide various glove types, including latex, nitrile, and vinyl, catering to diverse industry applications. Confirm the supplier’s ability to provide detailed product specifications, such as thickness, tensile strength, and resistance levels, to match your operational needs. Evaluate their minimum order quantities and assess whether they offer scalable supply options to accommodate business growth or fluctuating demand. Investigate their stock management practices, ensuring they can maintain sufficient inventory levels to prevent shortages. Check for transparent shipping policies and costs, particularly for regional or remote delivery. Additionally, ensure they have a responsive support team to handle technical queries or order adjustments efficiently, as this demonstrates a strong commitment to customer service.

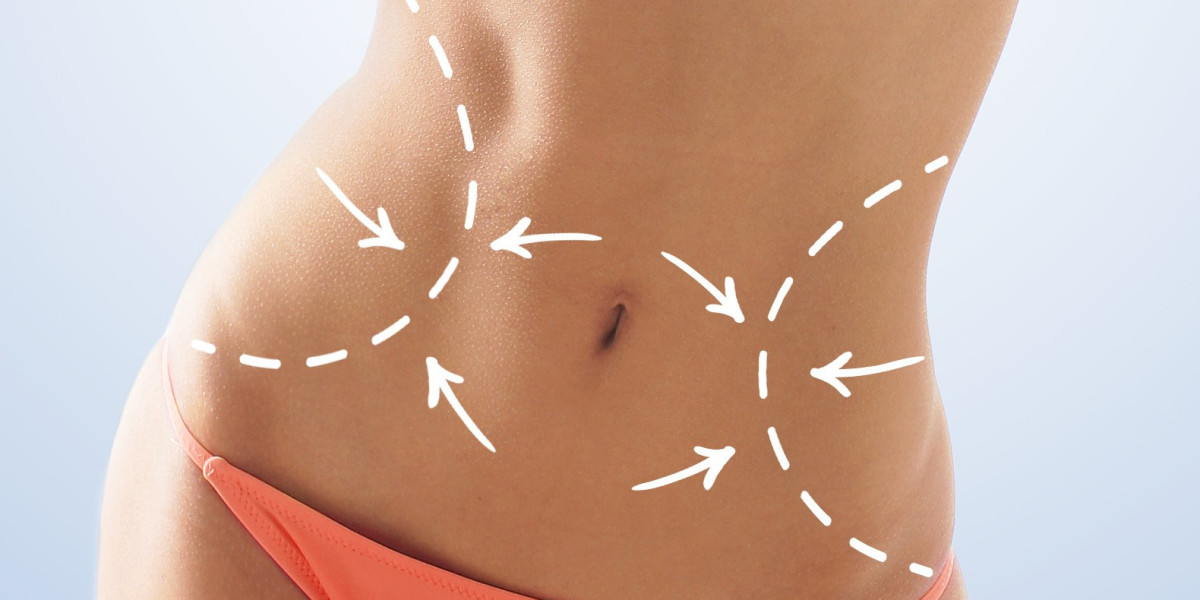

The Different Types of Disposable Gloves Available

Disposable gloves are available in various materials, each designed for specific applications. Latex gloves are widely used due to their flexibility and snug fit, offering excellent tactile sensitivity. However, they are unsuitable for users with latex allergies. Nitrile gloves are a preferred alternative, known for their puncture resistance and chemical protection, making them ideal for medical, industrial, and laboratory use. Vinyl gloves are cost-effective and suitable for low-risk tasks where frequent glove changes are required, such as food handling. Additionally, polyethylene gloves, though less durable, are an economical option for short-term use in industries like food preparation.

Understanding Powdered vs Powder-Free Gloves

Powdered gloves assist in easy donning but may not be suitable for sensitive environments, while powder-free gloves, treated to reduce residue, are ideal for sterile or allergen-conscious applications.

Ensuring Supplier Reliability and Trustworthiness

Assess the supplier’s track record by reviewing their history of fulfilling commitments and meeting delivery timelines. Investigate their reputation through independent reviews, testimonials, or industry references to gauge their reliability. Confirm the supplier’s adherence to relevant certifications and standards, ensuring they provide gloves that meet safety and quality requirements specific to your sector. Establish clear communication channels to address potential issues swiftly and maintain transparency. Enquire about their contingency plans for managing disruptions, such as sudden demand spikes or supply chain challenges, as this demonstrates their preparedness and adaptability. Evaluate their financial stability to ensure they can sustain operations and fulfil long-term contracts. Build trust by initiating smaller orders initially, progressively increasing volumes as their reliability is proven. A proactive approach to relationship management strengthens trust and ensures a dependable partnership over time.

Assessing Cost-effectiveness and Pricing Structures

To evaluate cost-effectiveness, begin by analysing suppliers’ pricing structures, including unit costs and bulk discounts. Request detailed quotes, ensuring transparency regarding hidden charges such as shipping fees or additional taxes. Compare multiple suppliers to identify the best balance between price and quality. Consider scalability options, such as discounted rates for larger orders, to support future growth. Assess payment terms offered, such as credit options or flexible payment plans, to improve cash flow management. Investigate any loyalty programmes or incentives for repeat customers that could reduce overall costs. Ensure pricing aligns with the durability and quality of the gloves provided, avoiding overly cheap options that compromise performance. Maintain ongoing communication with suppliers to negotiate better terms as order volumes increase, fostering mutually beneficial agreements. Finally, assess potential cost savings through partnerships with local suppliers to reduce logistics expenses.

How to Check for Consistent Product Quality

Regularly inspect glove batches for uniformity in material thickness, elasticity, and finish to confirm compliance with safety standards. Collaborate with the supplier to obtain detailed product specifications, ensuring each batch matches agreed-upon criteria.

Establish a Comprehensive Quality Control Programme

Implement a structured inspection routine, including visual checks and practical testing, such as assessing tensile strength and puncture resistance, to identify any defects. Maintain proper documentation of inspection results for traceability.

Request quality assurance certifications, such as test reports or compliance documentation, directly from the supplier for transparency. Schedule on-site visits or audits to assess the supplier’s production processes, verifying adherence to quality protocols.

Promptly address any discrepancies by maintaining open communication with the supplier, requesting corrective actions or replacements when necessary. This proactive approach prevents the recurrence of quality issues, safeguarding your operational standards.

Exploring Supplier Delivery and Logistics

Efficient delivery and robust logistics are critical for ensuring a steady supply of disposable gloves. Begin by evaluating the supplier’s shipping options, including speed, reliability, and coverage, especially for remote or regional areas. Discuss delivery schedules to align with your inventory requirements and avoid unnecessary delays. Investigate the supplier’s packaging practices to confirm they protect products during transit and reduce waste.

The Importance of Customer Service in Supplier Selection

Here’s a detailed set of five H3 subheadings on “The Importance of Customer Service in Supplier Selection”, each with a long description suitable for a blog or article:

1. Builds Trust and Reliability

Exceptional customer service from a supplier establishes trust and demonstrates reliability. When suppliers respond promptly, address concerns effectively, and communicate transparently, businesses can feel confident in their partnership. Trustworthy suppliers are more likely to deliver products on time and resolve issues efficiently, reducing the risk of disruptions and ensuring a smoother operational workflow.

2. Enhances Problem-Solving and Support

Suppliers with strong customer service provide valuable support during challenges, such as delays, defective products, or technical issues. Effective problem-solving capabilities ensure that problems are addressed quickly and professionally, minimizing downtime and financial losses. A supplier that prioritizes customer service can become a dependable partner in overcoming operational hurdles.

3. Facilitates Clear Communication and Expectations

Good customer service ensures that both parties maintain open, clear, and consistent communication. Suppliers who actively listen, clarify requirements, and provide accurate information reduce misunderstandings and errors. Clear communication helps businesses set realistic expectations, plan effectively, and maintain smooth day-to-day operations without costly missteps.

4. Improves Long-Term Partnerships

Suppliers who prioritize customer service contribute to stronger, long-term relationships. Businesses are more likely to continue working with suppliers who demonstrate care, responsiveness, and reliability. These enduring partnerships foster loyalty, mutual understanding, and collaboration, which can lead to better pricing, customized solutions, and preferential treatment over time.

5. Supports Business Reputation and Customer Satisfaction

A supplier’s level of customer service can indirectly affect a company’s reputation. Timely deliveries, quality products, and responsive support help businesses meet their own customer expectations consistently. Choosing suppliers with excellent customer service ensures that a company can maintain high standards, ultimately improving client satisfaction and fostering trust in the marketplace.

Comparing Online and Offline Disposable Glove Suppliers

When comparing online and offline disposable glove suppliers, consider the distinct advantages and limitations of each. Online suppliers often provide broader product ranges and detailed specifications, offering convenience for businesses requiring bulk purchases or niche products. Digital platforms may feature reviews and ratings, assisting with informed decisions, while automated systems can streamline reordering processes. However, shipping delays or issues with product returns may arise. Offline suppliers, particularly local distributors, allow physical inspection of gloves to verify quality before purchase. Face-to-face interaction fosters stronger communication, enabling tailored recommendations and faster issue resolution. Offline options also benefit businesses with urgent or last-minute requirements, as local suppliers can often provide immediate stock availability. When choosing, assess your business’s specific needs, balancing convenience, cost, and accessibility to ensure optimal supply chain efficiency.

Understanding Environmental Considerations

As businesses increasingly prioritise sustainability, integrating eco-conscious practices in disposable glove procurement becomes essential. Start by researching suppliers who offer biodegradable or compostable gloves, reducing long-term environmental impact. Evaluate the production processes of potential suppliers, ensuring they minimise energy use and waste. Pay attention to whether their manufacturing facilities utilise renewable energy sources or adhere to environmentally friendly standards, such as ISO 14001.

Consider the packaging used for glove shipments; opt for suppliers who use recyclable or minimal packaging materials to decrease overall waste. Assess their efforts in reducing transportation emissions, such as partnering with local distributors or using efficient logistics networks. H3 Certifications and Industry Standards Verify suppliers hold certifications that confirm their adherence to environmental standards, such as FSC-certified packaging or compliance with sustainable manufacturing practices.

Engage with suppliers who actively invest in research to innovate sustainable glove materials, reflecting their long-term commitment to environmental responsibility. Collaborating with such suppliers aligns your business with sustainable development goals.

Developing Long-term Relationships with Suppliers

Building long-term relationships with suppliers requires consistent engagement and proactive communication. Begin by establishing clear expectations regarding quality, delivery timelines, and pricing in a formal agreement. Schedule regular check-ins to discuss performance, address potential concerns, and explore opportunities for improvement. Demonstrate loyalty by prioritising repeat orders and maintaining steady business, even during fluctuating market conditions.

Collaborate on innovative solutions, such as sustainable product alternatives or improved logistics, to enhance mutual benefits and strengthen the partnership. Offer constructive feedback and acknowledge their efforts in meeting or exceeding expectations, fostering a positive working dynamic.

Invest in understanding your supplier’s operations by arranging site visits or attending industry events where they are present. This not only improves trust but also provides insights into their capabilities and limitations. Maintain flexibility in negotiations, accommodating occasional setbacks while ensuring accountability. By fostering mutual respect and open dialogue, both parties can develop a partnership that supports long-term success and reliability.

How to Evaluate Supplier Performance Regularly

Establish a structured framework to measure supplier performance against key benchmarks such as product quality, delivery accuracy, and responsiveness. Use performance indicators to assess compliance with agreed standards and timelines. Schedule periodic reviews to discuss performance metrics and identify areas requiring improvement.

Maintain detailed records of previous transactions, including instances of delayed shipments or quality discrepancies, to evaluate trends over time. Engage in open communication with suppliers during assessments to encourage transparency and collaborative problem-solving.

Incorporate feedback from relevant departments, such as procurement or operations, to gain insights into the supplier’s impact on your processes. Request regular updates from the supplier on their operations, including any changes in manufacturing or logistical capabilities that might affect service.

Consider conducting supplier audits or site visits to directly observe their processes and assess compliance with industry regulations and certifications. Continuously compare the supplier’s performance with other market options to ensure competitive service delivery and identify potential alternatives, if necessary.

H3 Exploring Future Trends in Disposable Gloves Industry

Advancements in disposable glove technology are driving significant changes in the industry. New materials, such as hybrid polymers, are emerging, offering enhanced flexibility, durability, and resistance to chemicals. The focus on antimicrobial gloves is also growing, particularly in healthcare and food handling, where reducing contamination risks is critical. Automated manufacturing processes are improving efficiency, allowing suppliers to meet rising demand without compromising quality. H3 The Rise of Sustainable Alternatives in Glove Production The industry is witnessing a shift towards biodegradable gloves and materials sourced from renewable resources, addressing environmental concerns. Digital supply chain solutions, such as real-time inventory tracking and predictive analytics, are being adopted to streamline procurement and logistics. Additionally, customisation options, including gloves tailored for specific tasks or ergonomic designs, are becoming increasingly available, helping businesses achieve superior performance and user comfort.

Conclusion

To ensure a productive partnership with your disposable gloves supplier, focus on fostering effective communication and mutual understanding from the outset. Clearly outline your expectations regarding quality, delivery timelines, and adherence to industry standards. Regularly assess supplier performance using measurable benchmarks, such as product consistency, delivery reliability, and customer service responsiveness. Address any discrepancies promptly, maintaining open dialogue to identify solutions collaboratively. Prioritise suppliers who demonstrate adaptability, such as managing fluctuating demand or introducing innovative glove options. Engage with suppliers that align with your business values, including sustainability or ethical sourcing practices. Maintain comprehensive records of transactions, inspections, and feedback to track supplier performance over time. Additionally, actively participate in discussions about market trends and technological advancements to ensure your supplier can continue meeting evolving needs effectively. This strategic approach ensures a seamless supply chain, supporting operational excellence.

6 faqs

1. How can I identify a trustworthy disposable gloves supplier?

Research Disposable Gloves Supplier with certifications, customer testimonials, and a history of reliability in delivering quality products.

2. What steps can I take to verify product quality?

Request product samples, review certifications, and conduct regular quality inspections to ensure compliance with standards.

3. Are powder-free gloves better than powdered gloves?

Powder-free gloves are suitable for sterile and allergen-sensitive environments, whereas powdered gloves ease donning but may cause residue issues.

4. What is the difference between latex and vinyl gloves?

Latex gloves offer better flexibility, while vinyl gloves are cost-effective and ideal for low-risk tasks.

5. How can I manage fluctuating glove demand?

Work with suppliers offering scalable options and flexible inventory management.

6. What role does customer service play in supplier selection?

Responsive customer service ensures efficient issue resolution and seamless order management.

Related Business Listings |