In today’s fast-evolving manufacturing landscape, precision, efficiency, and reliability are more than just desirable—they’re essential. One technology leading this transformation is the fiber laser welder, a cutting-edge solution that has become indispensable across industries from automotive and aerospace to electronics and jewelry. For companies seeking superior welding performance, understanding why fiber laser welding stands out is key to staying competitive.

Unmatched Accuracy and Efficiency

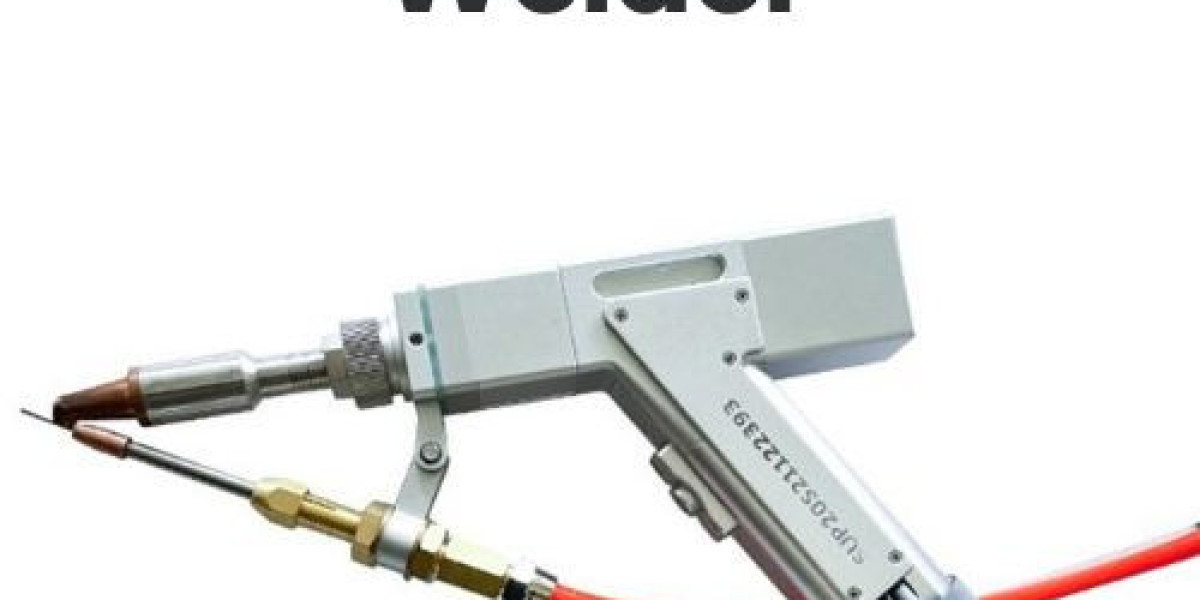

A fiber laser welder offers exceptional control and accuracy, enabling users to produce cleaner and stronger welds with minimal distortion. Unlike traditional welding methods, it uses a focused laser beam that precisely melts and fuses materials, eliminating the need for filler metals. This results in smoother seams and a superior finish—ideal for applications demanding microscopic precision or aesthetic perfection.

Because of its energy efficiency, the fiber laser welder reduces operational costs and power consumption. Its high beam quality ensures deeper penetration with less heat, which translates to faster processing speeds and reduced rework.

Versatility Across Materials and Applications

From stainless steel and aluminum to titanium and copper, the fiber laser welder adapts effortlessly to different metals and thicknesses. This flexibility makes it a preferred choice for industries requiring both fine detail and structural integrity.

Manufacturers use fiber laser welding systems for tasks such as battery tab welding, medical device fabrication, and high-end electronic assembly. Its ability to produce repeatable, high-quality welds makes it ideal for automated production lines and robotic integration.

Minimal Maintenance and Long Service Life

One of the key advantages of a fiber laser welder is its durability. Unlike gas or CO₂ lasers, fiber lasers have fewer moving parts and no mirrors, significantly reducing maintenance needs. The solid-state design ensures long operational life, lower downtime, and consistent output quality.

With the right setup, the fiber laser welder can operate continuously for thousands of hours with minimal intervention—making it an investment that pays off in both performance and reliability.

LaserChina: Pioneering Excellence in Laser Welding Technology

For businesses seeking innovation and reliability, LaserChina stands out as a trusted name in the laser equipment industry. With years of expertise in developing and manufacturing advanced laser systems, LaserChina provides world-class fiber laser welders designed for precision, speed, and long-term dependability.

Their equipment integrates the latest in optical technology, intuitive software, and ergonomic design—ensuring users achieve the highest quality results with maximum productivity. Whether for small-scale production or industrial automation, LaserChina’s fiber laser welders are engineered to meet the most demanding requirements.

Final Thoughts

As industries continue to evolve toward automation and precision engineering, investing in a fiber laser welder has become a strategic choice for forward-thinking manufacturers. The combination of accuracy, efficiency, and low maintenance makes it an indispensable tool in modern production.

By partnering with LaserChina, businesses can unlock new levels of productivity and performance—bringing precision and power together in every weld.