In demanding industries, no two machines operate under the exact same conditions. Yet many businesses still rely on standard bearings that fail to match their unique requirements. The result? Frequent breakdowns, higher maintenance costs, and reduced efficiency. If your machinery is struggling to perform optimally, a customized bearing may be the solution you’ve been missing.

The Cost of Using Standard Bearings Everywhere

Generic bearings are built for general purposes, but they often fall short in specialized applications. Common problems include:

Premature wear due to misalignment or unusual load conditions

Excessive friction and overheating under heavy loads

Frequent replacements leading to higher operational costs

Reduced efficiency and inconsistent performance

Costly downtime affecting production schedules

For industries such as robotics, medical equipment, aerospace, and heavy machinery, these issues can seriously impact productivity and profitability.

Why Customized Bearings Make a Difference

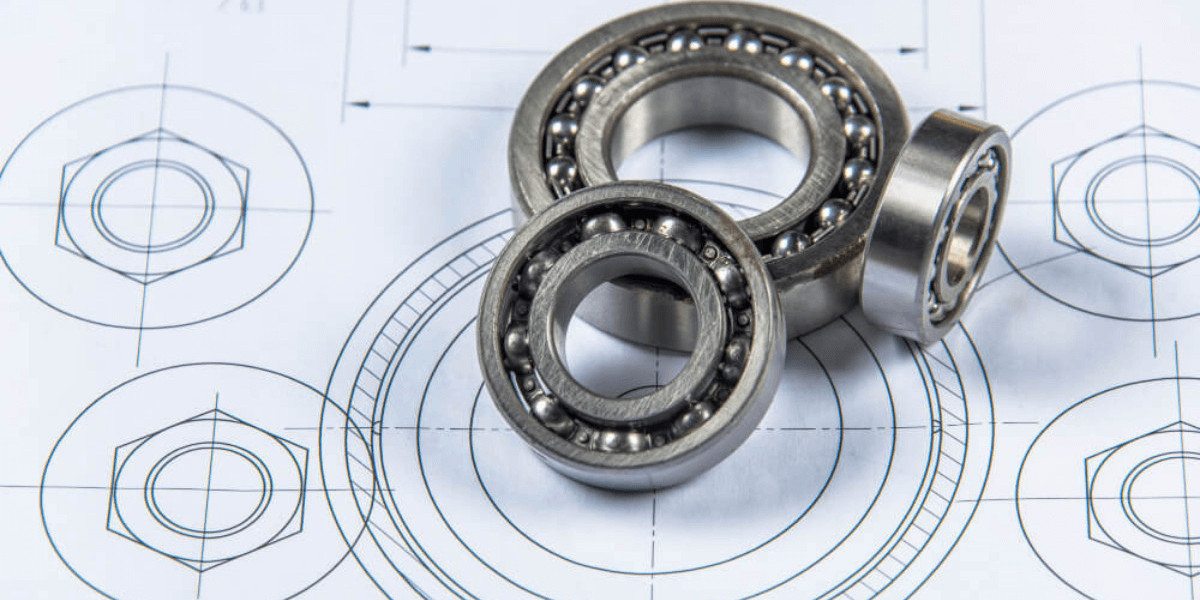

A customized bearing is engineered specifically for your machine’s requirements. By tailoring the design, size, material, and performance features, customized solutions ensure longer lifespan, greater reliability, and smoother operation under unique working conditions.

Key Benefits of Customized Bearings

Precision Fit: Designed to handle exact load requirements.

Durability: Made with materials suited for harsh or unique environments.

Efficiency: Reduced energy loss due to optimized design.

Long-Term Savings: Fewer replacements and lower downtime costs.

How Yuwei Customized Bearings Solve Industry Challenges

1. Tailored Engineering

Yuwei develops bearings that match client-specific needs, whether it’s for extreme temperatures, heavy loads, or precision movements.

2. Versatile Applications

From robotics and automation to aerospace and agriculture, Yuwei offers customized bearing solutions across multiple industries.

3. Advanced Manufacturing

Using modern technology and strict quality controls, Yuwei ensures each custom product meets international standards for performance and durability.

4. Lower Total Cost of Ownership

While customized solutions may cost more initially, they pay off by extending machine life, improving efficiency, and reducing frequent replacements.

Industries That Rely on Customized Bearings

Robotics: For precision and smooth, controlled movements.

Medical Equipment: Ensuring reliability in surgical and diagnostic devices.

Aerospace: Withstanding extreme conditions and maintaining accuracy.

Heavy Machinery: Handling heavy-duty loads with long-term durability.

Why Yuwei Bearing Is the Right Partner

Choosing the right supplier is just as important as choosing the right product. Yuwei has years of expertise in engineering and manufacturing customized bearings. With a strong focus on quality, innovation, and customer needs, Yuwei has become a trusted partner for industries worldwide.

Final Thoughts

If you’re frustrated with frequent failures, inefficiency, and mounting maintenance costs, the problem may not be your equipment—but your bearings. Investing in Yuwei customized bearings ensures long-term reliability, smoother performance, and cost savings for your business.