Ebonite, also known as hard rubber, is a highly durable and chemically resistant material used to line tanks, pipes, valves, and other equipment to protect them from corrosion and wear. This lining significantly extends equipment life and reduces maintenance costs.

In this blog, we will explore what ebonite rubber lining is, its properties, applications, installation process, and benefits in industrial environments.

What is Ebonite?

Ebonite is a hard, rigid form of rubber produced by vulcanizing natural rubber with a high percentage of sulfur (typically 30–40%). The high sulfur content gives it:

High hardness

Excellent chemical resistance

Good mechanical strength

Superior durability

Unlike soft rubber linings, ebonite is rigid and provides stronger resistance against harsh chemical attacks.

What is Ebonite Rubber Lining?

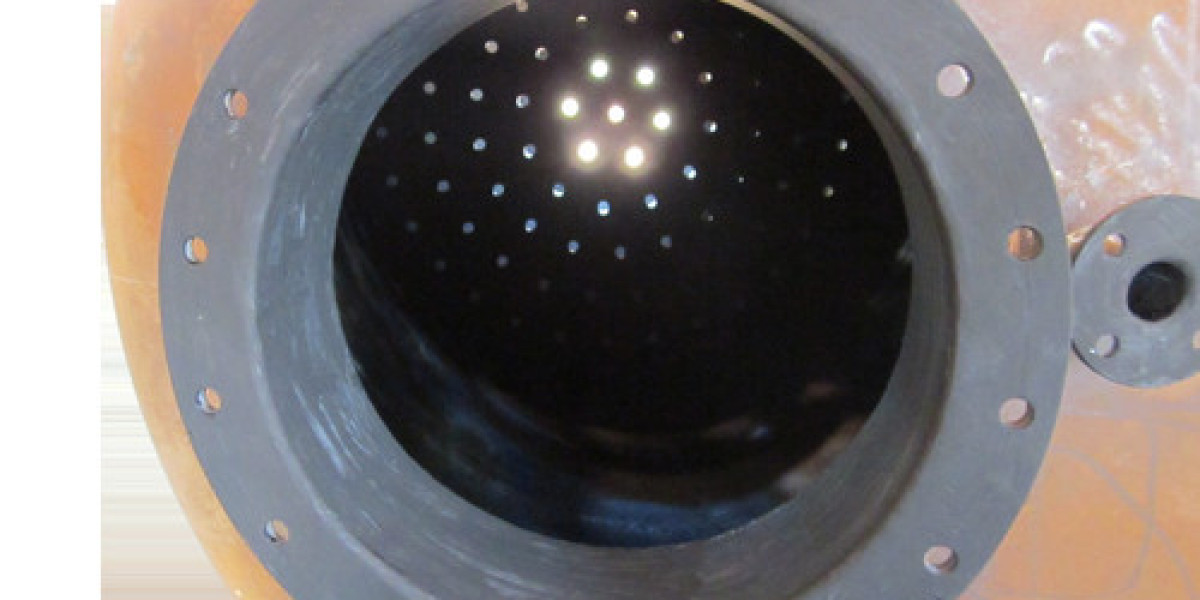

Ebonite rubber lining is a corrosion-resistant protective layer applied to the internal surfaces of metal equipment. The lining acts as a barrier between corrosive substances and the metal substrate.

It is commonly applied to:

Storage tanks

Reaction vessels

Pipes and fittings

Pumps and valves

Agitators

Chimneys and ducts

The lining thickness usually ranges from 3 mm to 6 mm, depending on the application and exposure conditions.

Key Properties of Ebonite Rubber Lining

1. Excellent Chemical Resistance

Resists strong acids like:

Sulfuric acid

Hydrochloric acid

Phosphoric acid

2. High Hardness

Provides better abrasion resistance compared to soft rubber linings.

3. Low Permeability

Prevents penetration of corrosive chemicals.

4. Strong Adhesion to Metal

Ensures long-term bonding with steel surfaces.

5. Temperature Resistance

Typically withstands temperatures up to 100°C (depending on formulation).

Applications of Ebonite Rubber Lining

1. Chemical Processing Industry

Used in acid storage tanks, reactors, and pipelines.

2. Fertilizer Plants

Protects equipment from corrosive chemicals.

3. Water Treatment Plants

Used in clarifiers, tanks, and piping systems.

4. Pharmaceutical Industry

Used where chemical purity and corrosion protection are critical.

5. Mining & Metallurgy

Protects slurry tanks and process vessels.

Installation Process of Ebonite Rubber Lining

Proper installation is crucial for long-term performance.

Step 1: Surface Preparation

Metal surface is grit blasted.

Removes rust, oil, and contaminants.

Achieves proper surface roughness.

Step 2: Application of Adhesive

Special bonding agents are applied.

Ensures strong adhesion between rubber and metal.

Step 3: Lining Application

Ebonite sheets are applied manually.

Joints are carefully sealed.

Step 4: Vulcanization

Heat curing process.

Converts rubber into hard ebonite.

Enhances chemical resistance and strength.

Step 5: Inspection & Testing

Spark testing for pinholes.

Thickness measurement.

Visual inspection.

Proper curing and inspection ensure a defect-free lining.

Advantages of Ebonite Rubber Lining

1. Superior Corrosion Protection

Provides long-term resistance in acidic environments.

2. Extended Equipment Life

Prevents metal degradation and structural damage.

3. Cost-Effective

Lower replacement and maintenance costs.

4. Abrasion Resistance

Suitable for moderate wear applications.

5. Strong Bonding

Minimizes risk of peeling or blistering.

Ebonite vs Soft Rubber Lining

| Feature | Ebonite Lining | Soft Rubber Lining |

|---|---|---|

| Hardness | High | Low |

| Flexibility | Rigid | Flexible |

| Chemical Resistance | Excellent | Very Good |

| Abrasion Resistance | Better | Moderate |

| Impact Resistance | Lower | Higher |

Ebonite lining is ideal for strong chemical exposure, while soft rubber is preferred for impact-heavy environments.

Limitations of Ebonite Rubber Lining

Not suitable for high-impact applications

Limited flexibility

Temperature restrictions

Requires skilled installation

Selecting the right lining material depends on the operating conditions.

Maintenance and Inspection

To ensure long-term performance:

Conduct periodic spark testing

Inspect for cracks or blistering

Avoid mechanical damage

Monitor chemical compatibility

If properly installed and maintained, ebonite lining can last many years without major repairs.

Conclusion

Ebonite rubber lining is a highly effective corrosion protection solution for industries handling aggressive chemicals. Its high hardness, chemical resistance, and durability make it ideal for tanks, pipes, and process equipment.

Although it requires careful installation and proper curing, the long-term benefits outweigh the initial investment. For industries looking to protect valuable assets from corrosion, ebonite rubber lining remains one of the most trusted and reliable protective systems.

Choosing the right lining solution ensures safety, durability, and operational efficiency in demanding industrial environments.