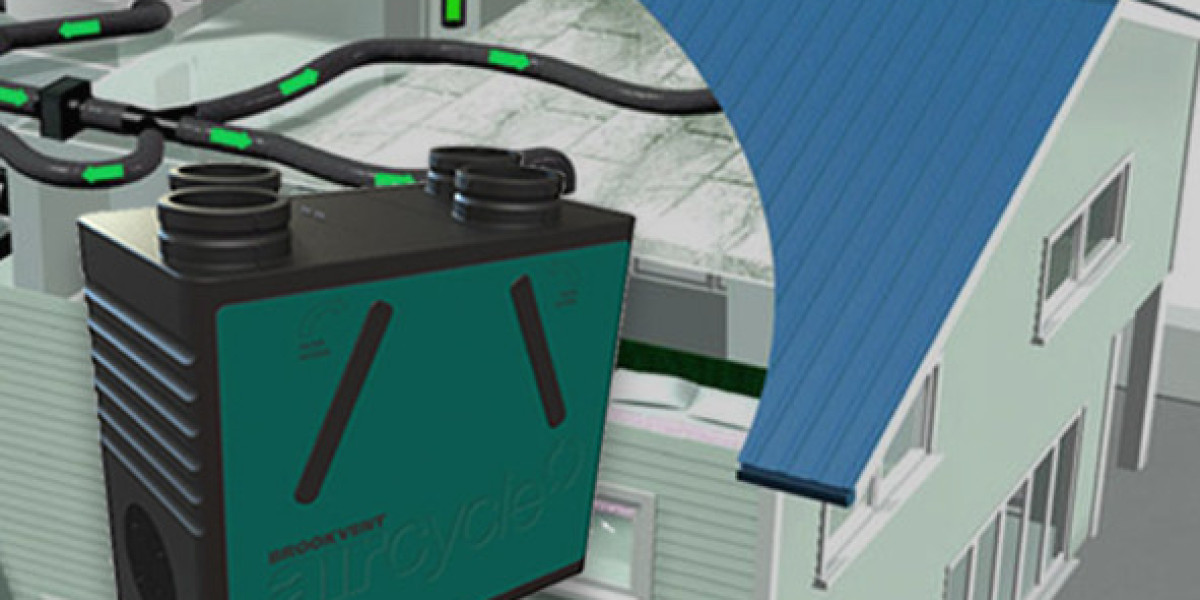

Understanding airflow patterns within buildings is crucial for ensuring effective Mechanical Ventilation and maintaining indoor air quality. Airflow is influenced by factors such as building layout, structural design, and external environmental conditions. Poorly planned airflow can lead to areas of stagnation, where air becomes trapped, or zones of excessive flow, which may cause discomfort. Proper consideration must be given to how air naturally moves through spaces, including the impact of open doors, windows, and partitions.

Furthermore, factors such as ceiling height and vent placement play a significant role in directing airflow efficiently. By studying these patterns, designers can identify potential issues and implement solutions that promote uniform air distribution. This ensures that occupied spaces are consistently supplied with fresh air while stale air is effectively removed. Detailed analysis of airflow patterns during the design phase helps avoid inefficiencies that might otherwise hinder the performance of Forced Air Ventilation systems.

Common Mistakes in Ventilation Layouts

Neglecting the specific needs of a building when designing ventilation layouts is a frequent oversight. Each structure has unique characteristics that influence its ventilation requirements, yet a one-size-fits-all approach is often applied. Incorrect sizing of ducts and vents is another common issue, leading to either insufficient or excessive airflow. This miscalculation can disrupt the balance of air distribution, compromising the comfort and functionality of indoor spaces.

Positioning ventilation components without consideration for the natural flow of air can also create inefficiencies. Poorly placed vents may cause uneven air circulation, with some areas receiving inadequate ventilation while others experience excessive draughts. In addition, failing to design systems that account for varying occupancy levels or room functions can result in energy wastage and diminished indoor air quality.

Another recurring mistake is selecting materials that are not suited to the system's requirements. High-resistance materials or components that generate excessive noise can reduce system efficiency and cause discomfort for occupants. Furthermore, failing to ensure the accessibility of system components for maintenance can lead to complications during routine servicing, contributing to performance deterioration over time.

Lastly, improper ductwork sealing is often overlooked, leading to air leakage. These leaks reduce overall system efficiency and can increase energy consumption, underscoring the importance of precision during installation.

Choosing the Right Forced Air Ventilation System

Selecting an appropriate Forced Air Ventilation system requires careful consideration of the building's unique requirements and environmental conditions. Factors such as occupancy levels, building size, and intended use influence the choice of system. Below are key aspects to consider when making a selection.

Understanding System Types

Different systems are designed for varying purposes, such as supply-only, exhaust-only, or balanced ventilation. Each type offers specific advantages depending on the desired airflow pattern and energy efficiency goals.

Evaluating Energy Efficiency

Energy consumption is a critical factor in system selection. Opting for energy-efficient systems can significantly reduce operating costs while supporting sustainability goals. Features such as energy recovery ventilators and variable-speed fans improve efficiency.

Accounting for Climate Conditions

The local climate plays a substantial role in determining system specifications. In colder regions, systems with heat recovery features may be more suitable, while in warmer climates, additional cooling capabilities integrated into the ventilation design may be more suitable.

Considering Building Scale and Layout

The size and structural layout of a building must inform system design. Larger buildings often require more complex systems with zoning capabilities to ensure even air distribution across multiple spaces.

Prioritising Indoor Air Quality

Selecting systems equipped with advanced filtration technologies is essential for maintaining high indoor air quality. Filters that capture particulates, allergens, and other pollutants enhance occupant comfort and health, especially in environments with specific air-purity requirements.

Placement Strategies for Maximum Efficiency

Effective placement of ventilation components requires careful consideration of airflow dynamics and the building's architectural layout. Positioning ducts and vents to complement the natural movement of air is essential for maintaining consistent circulation and ensuring that fresh air reaches all occupied areas. Intake vents are most effective when located in areas where air can enter unobstructed. In contrast, exhaust vents should be placed to facilitate the removal of stale air, avoiding zones prone to stagnation.

Obstructions such as furniture, partitions, or structural features must be assessed to prevent them from impeding airflow. The alignment of vents and ducts should allow for unobstructed pathways, reducing the likelihood of uneven air distribution. Furthermore, proximity to heat sources or cooling systems should be managed to prevent airflow imbalances.

In multi-storey buildings, strategically positioning components at different levels helps air move between floors. Incorporating ceiling-mounted vents can improve vertical airflow, while wall-mounted options better suit spaces with specific circulation needs. Placement should also account for maintenance accessibility, ensuring components can be serviced without disrupting building operations. Overall, thoughtful positioning promotes efficient airflow management, contributing to a well-regulated indoor environment and optimising system performance.

Balancing Intake and Exhaust for Optimal Performance

Achieving an effective balance between intake and exhaust components in a Forced Air Ventilation system is critical for maintaining consistent air circulation and ensuring stable internal conditions. A carefully designed system considers the sizing and positioning of both intake and exhaust vents to prevent the development of pressure disparities within the building. Disparities in pressure can lead to undesirable effects, such as draughts or restricted airflow in certain areas.

Calibration of fans is vital for regulating airflow rates, ensuring that the volume of air entering the system matches the volume expelled. This coordination enables the effective removal of stale air while ensuring a steady supply of fresh air throughout the building. Consideration must also be given to how external environmental factors, such as wind patterns, could influence the performance of intake and exhaust systems. These factors can inadvertently disrupt airflow balance if not accounted for during planning.

Proper sealing and insulation of ductwork also contribute to optimal performance, as leaks in the system can disrupt airflow regulation and lead to inefficiencies. Addressing these elements in the system design is essential to supporting its intended function and promoting a consistently comfortable, healthy indoor environment.

Using Zoning Techniques to Improve Air Distribution

Dividing a building into distinct zones based on specific ventilation needs enables a tailored approach to air distribution, thereby enhancing system efficiency. Each zone can be designed to address variations in occupancy, temperature requirements, or functional use. This strategy helps ensure energy is directed to areas where it is most needed, avoiding unnecessary consumption in less-occupied spaces.

In buildings with diverse activities or multiple floors, zoning can improve airflow control by assigning independent settings to each area. For example, conference rooms, kitchens, and storage spaces typically have differing ventilation demands. By grouping spaces with similar requirements, systems can be adjusted to optimise comfort and air quality without compromising energy efficiency.

Zoning techniques also facilitate the integration of advanced control systems, enabling dynamic adjustments based on real-time conditions. Sensors and programmable systems can monitor variables such as humidity, carbon dioxide levels, or temperature, automatically modifying airflow to maintain desired conditions. Furthermore, separating zones allows for better system maintenance, as individual components can be serviced without disrupting other areas.

Through strategic zoning, it becomes possible to address the diverse and changing ventilation requirements within a building while minimising energy waste and maintaining consistent environmental standards across all zones.

Incorporating Energy Recovery Systems for Savings

Energy recovery systems play a significant role in enhancing the energy efficiency of Forced Air Ventilation systems by reusing energy from exhaust air. These systems are particularly advantageous in environments with high heating or cooling demands, as they can help offset energy losses associated with temperature control. Devices such as heat recovery ventilators (HRVs) and energy recovery ventilators (ERVs) are designed to transfer heat or moisture between incoming and outgoing air streams, reducing the workload on heating or cooling equipment.

The effectiveness of energy recovery systems is influenced by factors such as climate, building design, and the space's ventilation requirements. In colder climates, these systems are often used to retain heat from exhaust air. At the same time, in warmer, more humid regions, they can help control excess moisture during ventilation. The integration of these systems can also support compliance with energy efficiency regulations, making them an appealing choice for modern buildings.

To maximise the performance of energy recovery systems, proper installation and regular upkeep are essential. Ensuring compatibility with the existing Forced Air Ventilation setup and selecting components suited to specific building needs are key considerations in achieving optimal results.

Material Selection to Reduce Noise and Resistance

Selecting materials that enhance airflow and minimise sound transmission is a critical aspect of designing effective ventilation systems. Materials with a smooth surface, such as galvanised steel or certain plastics, are often preferred for their ability to reduce friction in ductwork. Lower airflow resistance ensures air moves more efficiently through the system, reducing the energy required for operation.

In addition to optimising airflow, noise reduction is another important consideration. The use of sound-dampening materials, such as fibreglass insulation or acoustic linings, can help minimise noise from air movement and mechanical components. Strategically placed silencers or baffles within the duct network can further decrease sound levels, contributing to a more comfortable indoor environment.

Material durability is also a key factor, as components must withstand varying pressures and environmental conditions without compromising performance. Choosing materials that are corrosion- or wear-resistant helps prevent leaks or blockages that disrupt system efficiency. The selection process should take into account the specific demands of the building, including its size, occupancy levels, and environmental requirements, to ensure compatibility with the overall design.

Regular Maintenance Practices to Sustain Efficiency

Consistent upkeep of Forced Air Ventilation systems involves several key practices that support optimal functionality and energy performance. Filters must be cleaned or replaced according to the manufacturer's recommendations to maintain unobstructed airflow and prevent the accumulation of contaminants. Ductwork should be inspected periodically to identify and address any leaks, blockages, or signs of wear that could compromise system efficiency. The performance of fans and motors requires regular evaluation to ensure they operate within the intended parameters, avoiding unnecessary strain or energy use. Lubricating moving components as needed can further reduce wear and improve operational smoothness.

Monitoring system components for excessive noise or vibrations is also critical, as these can indicate underlying issues such as loose fittings or mechanical imbalances. Calibration of sensors and controls should be performed at intervals to maintain the accuracy of automated systems and preserve the intended indoor conditions. Scheduling routine checks for corrosion or damage in system materials ensures long-term durability. Maintenance logs can help track interventions and identify recurring issues, enabling more targeted adjustments that maintain the overall performance of the ventilation system.

Integrating Smart Controls for Modern Ventilation

Integrating smart controls into Forced Air Ventilation systems offers a sophisticated means of managing airflow and maintaining indoor air quality. These systems utilise advanced sensors to monitor variables such as temperature, humidity, and pollutant levels, enabling automated adjustments that respond to real-time conditions. By aligning ventilation rates with occupancy patterns or specific environmental needs, smart controls optimise energy use and support sustainable building operations.

Additionally, these technologies enable remote access and monitoring, allowing facility managers to oversee system performance and make necessary adjustments via digital platforms. Smart controls can also identify inefficiencies or maintenance requirements early, minimising potential disruptions and extending the system's lifespan.

Conclusion

Mechanical Ventilation design is essential for ensuring comfort, indoor air quality, and energy efficiency in modern buildings. By understanding airflow patterns, avoiding common layout mistakes, and selecting appropriate systems, designers can achieve balanced circulation throughout a structure. Incorporating strategies such as zoning, energy recovery, smart controls, and thoughtful material selection enhances performance while reducing operational costs. Regular maintenance ensures longevity and sustained efficiency. Ultimately, a well-designed Forced Air Ventilation system creates a healthier, more comfortable, and energy-conscious indoor environment, benefiting both occupants and facility managers.

FAQs

What is the importance of airflow analysis in buildings?

Airflow analysis helps identify stagnation zones, excessive draughts, and inefficient circulation, ensuring fresh air reaches all areas and stale air is removed effectively.

How does mechanical ventilation improve airflow efficiency?

Mechanical ventilation uses controlled airflow systems to regulate air distribution in different areas. By allowing separate control for each zone, it reduces energy waste while maintaining optimal comfort and air quality throughout the space.

Why is balancing intake and exhaust crucial?

Proper balance prevents pressure disparities, draughts, and uneven air distribution, maintaining consistent indoor conditions.

How do energy recovery systems contribute to savings?

They reuse energy from exhaust air to reduce heating or cooling loads, lowering energy consumption and operational costs.

What role do smart controls play in ventilation systems?

Smart controls monitor environmental variables and automate adjustments, optimising airflow, maintaining air quality, and improving energy efficiency.

Related Business Listings |